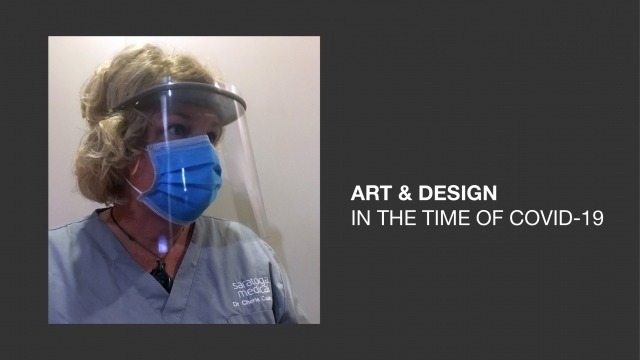

Shielding the front line: ANU 3D prints a solution for healthcare heroes

SHARE

ANU School of Art & Design Senior Lecturer, Rod Bamford is utilising his design expertise and 3D printer to prototype and manufacture flat-packed face shields that can be posted to general practitioners at the frontline of the COVID-19 crisis.

A number of designs developed by members of the Coronavirus Makers group have been uploaded to the open source web platform, Thingiverse, dedicated to the sharing of user-created digital design files. Using his home 3D printer, Bamford adapted and printed a number of these shields, which he then distributed to doctors and health care workers in his network for testing. Based on GPs feedback, Bamford has redesigned and printed a new version that includes slits for ventilation to prevent the shields from fogging up over time, adjusted visor fitting and comfort lining. Bamford has just sent out the first of these revised designs, and he will print and supply more face shields on demand. The improved design has also been published on Thingiverse so that people all around the world can use it to help their communities.

Bamford notes that, “the project is a perfect example of the benefits of a responsive distributed design and manufacture model – where prototypes are shared freely for others to adjust and produce locally using affordable and readily available materials and equipment. It really allows you to solve local problems in a customised way on the fly.”

The face shields are intended for use when the supply chains for protective equipment become strained. Bamford’s version of the face shield consists of simple materials – a 3D printed PLA visor and backstops, elastic bands, and a sheet of A4 overhead projector acetate. One face shield takes only half an hour to print and uses materials that cost less than a $1.50 per unit. The trade-off for this affordability is that some components of the shields have a limited lifespan, however, the careful design of each unit allows for the acetate screen component and the elastic bands to be quickly swapped out and replaced.

One of the key concerns for health care workers is that the materials used in the face shield need to be regularly and safely cleaned. Responding to this requirement, the PLA & PVC materials used in the 3D printer and the acetate sheets are both able to be cleaned using hospital grade disinfectant products.

To access the design file for the face shield, please see here.

For more information about the Coronavirus Makers Group, please see their website.